Materials: Small Scale Lab Testing

Regulatory Tests

The Small Scale lab facility performs many tests mandated in the Federal Aviation Regulations. The following is a brief explanation of the small-scale flammability tests performed at this facility:

The Ohio State (OSU) Rate of Heat Release Test is used to measure the rate at which heat energy is evolved by a material when burned. The heat release is measured for the duration of the test from the moment the specimen is injected into the controlled exposure chamber, and encompasses the period of ignition and progressive flame involvement of the surface.

The National Bureau of Standards (NBS) smoke chamber is the chamber used to determine the smoke generating charactersitics of airplane passanger cabin interior materials. It measures the amount of smoke produced per unit area by a material when exposed to both flaming and radiant heat sources.

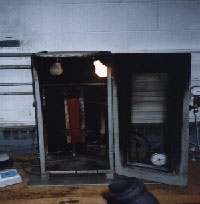

The Oil Burner Test for aircraft seats evaluates the burn resistance(burn length) and weight loss characteristics of aircraft seat cushions when exposed to a high-intensity oil burn flame.

The Oil Burner Test for cargo liner materials evaluates the flame penetration resistance capabilities of aircraft cargo compartment lining materials utilizing a high intensity oil burner flame.

Vertical Bunsen Burner Cabinet

The Vertical Bunsen Burner Test method is used for determining the resistance of cabin and cargo compartment materials when tested according to the 12-second or 60-second test specified in FAR 25.853 and FAR 25.855. Materials subjected to this test pass of fail based on burn length, after flame time, and drip flame time.

The Horizontal Bunsen Burner Test is used for determining the resistance of materials to flame when tested according to the 15-second horizontal bunsen burner tests specified in FAR 25.853. The pass/fail criterion is an average burn rate. Allowable burn rates are contingent on the materail as specified in the FAR.

The 45-Degree Bunsen Burner Test is used for determining the resistance of materials to flame penetration and to glow propagation when tested according to the 30-second, 45-degree Bunsen burner test specified in FAR 25.853.

The 60-Degree Bunsen Burner Test is used for determening the resistance of electrical wire insulation to flame when tested according to the 30-second and 60-second Bunsen burner test specified in FAR 25.869. The pass/fail criteria are based on the purn length, after flame time, and drip flame time.

Non-Regulatory Tests

A description of non regulatory tests which are included in the Aifcraft Materials Fire Test Handbook is given:

The Aircraft Blanket Test is intended for use in determining the resistance of aircraft blankets to flame when tested in the horizontal position and exposed the the Bunsen burner for 12-seconds. View this report

The Cotton Swab Test for Thermal/Acoustical Insulation Blankets is intended for use in determining the resistance of thermal/acoustical films to flame propogation when tested with alcohol dipped cotton swabs. View this report

The Smoke Test for Insulated Aircraft Wire is used to determine the smoke generating characteristics of insulated aircraft wire using a smoke density chamber.

For information contact:

OSU / NBS:

Mike Burns

(609) 485-4985

Seat Tests / Cargo Liner Tests:

Tim Salter

(609) 485-6962

Federal Aviation Administration

Federal Aviation Administration